GP ONE Tool

GP ONE Tool è il sistema avanzato che sta rivoluzionando la gestione e l’identificazione degli utensili. Grazie alla sua efficacia, questo strumento interagisce direttamente con le macchine CNC, migliorando la precisione e la qualità della produzione. Inoltre, GP ONE Tool consente di ridurre significativamente i tempi di cambio utensile, aumentando l’efficienza del processo produttivo.

Con GP ONE Tool, hai il controllo totale sulla gestione degli utensili, consentendoti di ottenere risultati straordinari nella tua attività produttiva.

Intuitivo e chiaro. Rapido e necessario.

Con GP ONE Tool puoi caricare rapidamente i tuoi utensili grazie alle tecnologie RFID o QR e averli disponibili a database in maniera ordinata con schede dedicate, divisi per magazzino.

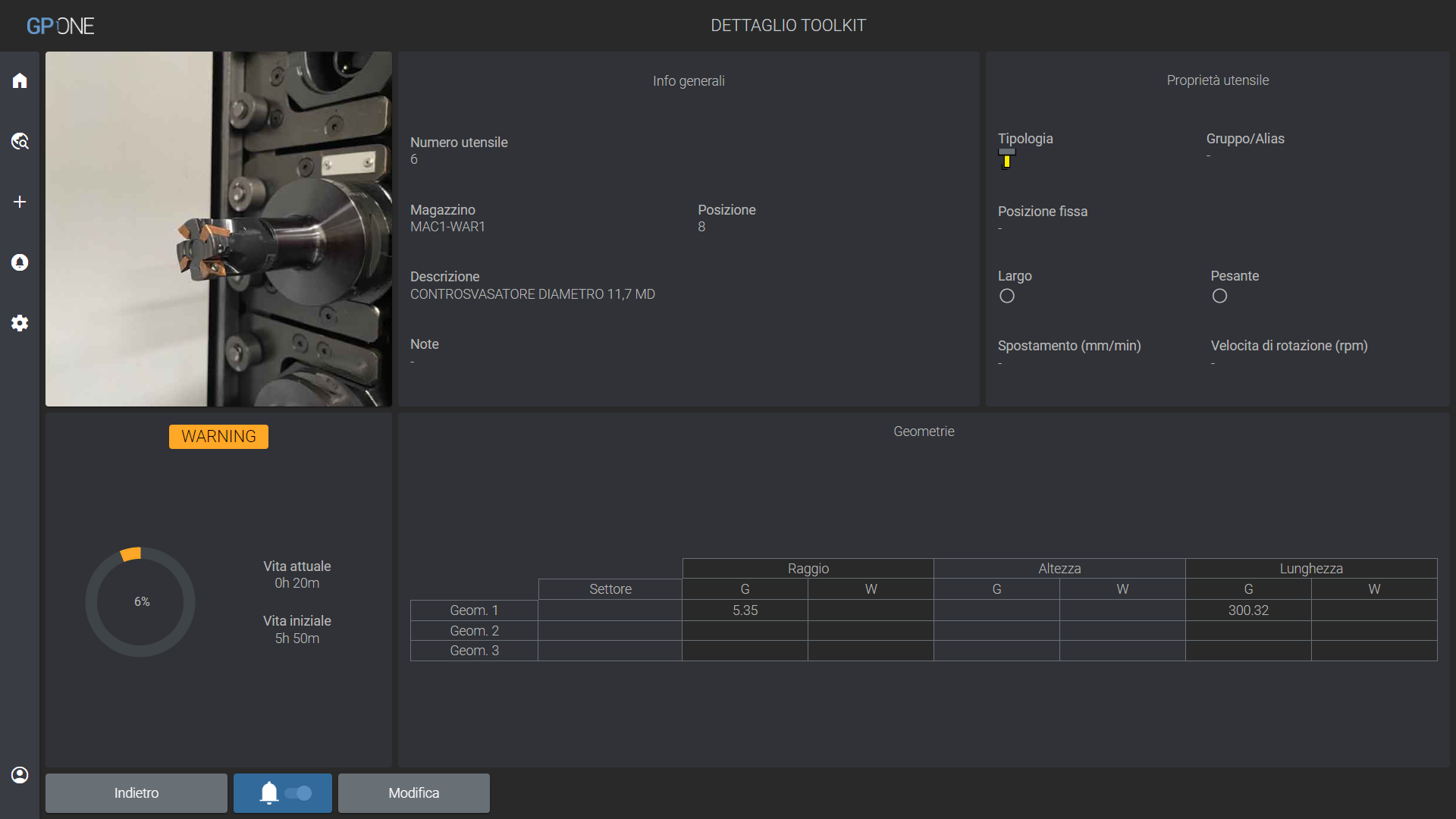

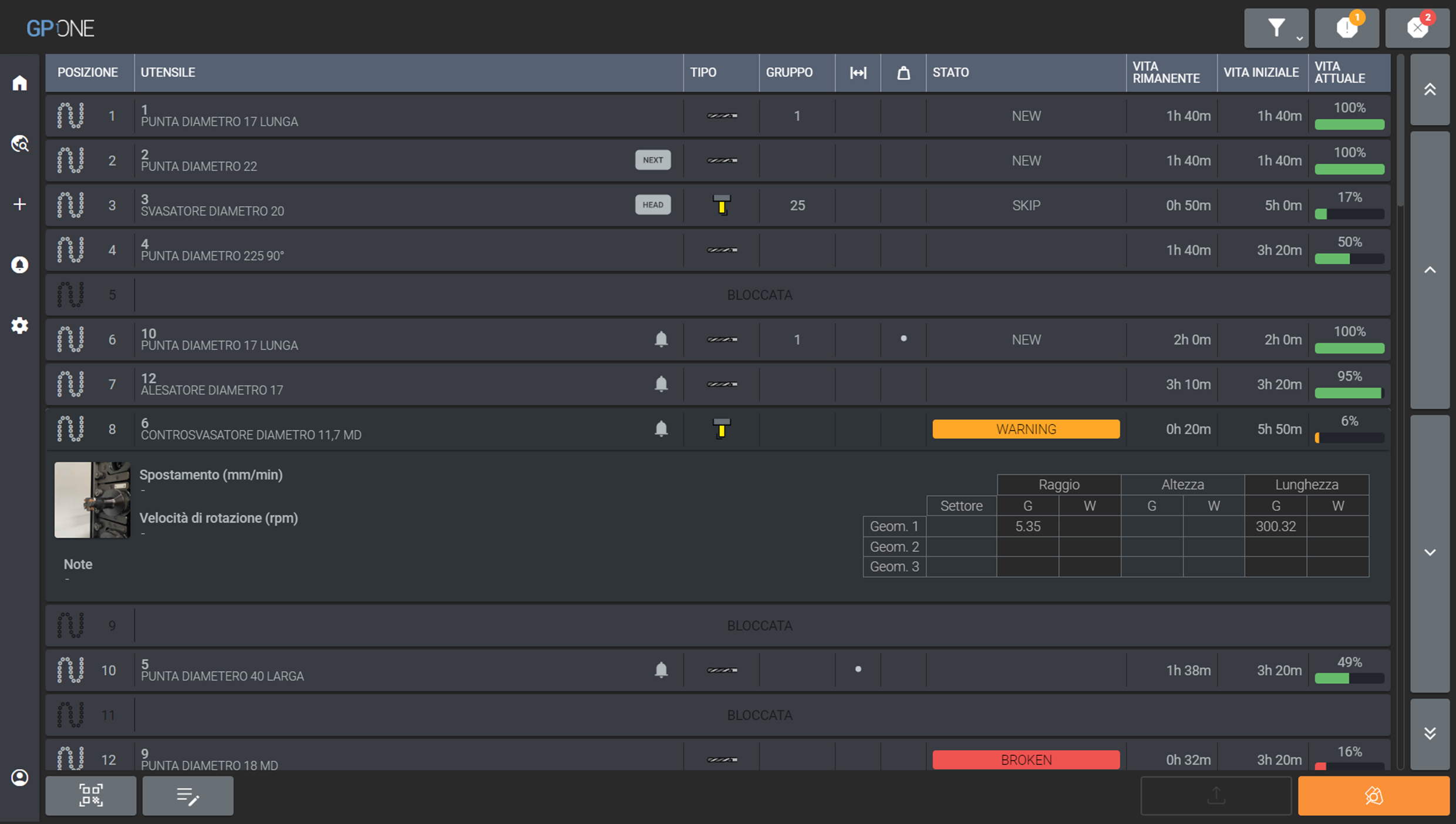

Tutti i dati dei tuoi utensili in real time.

Dentro le schede potrai trovare i dati in real time sul loro stato di usura, la foto dell’utensile e tutte le sue caratteristiche tecniche, anche modificabili.

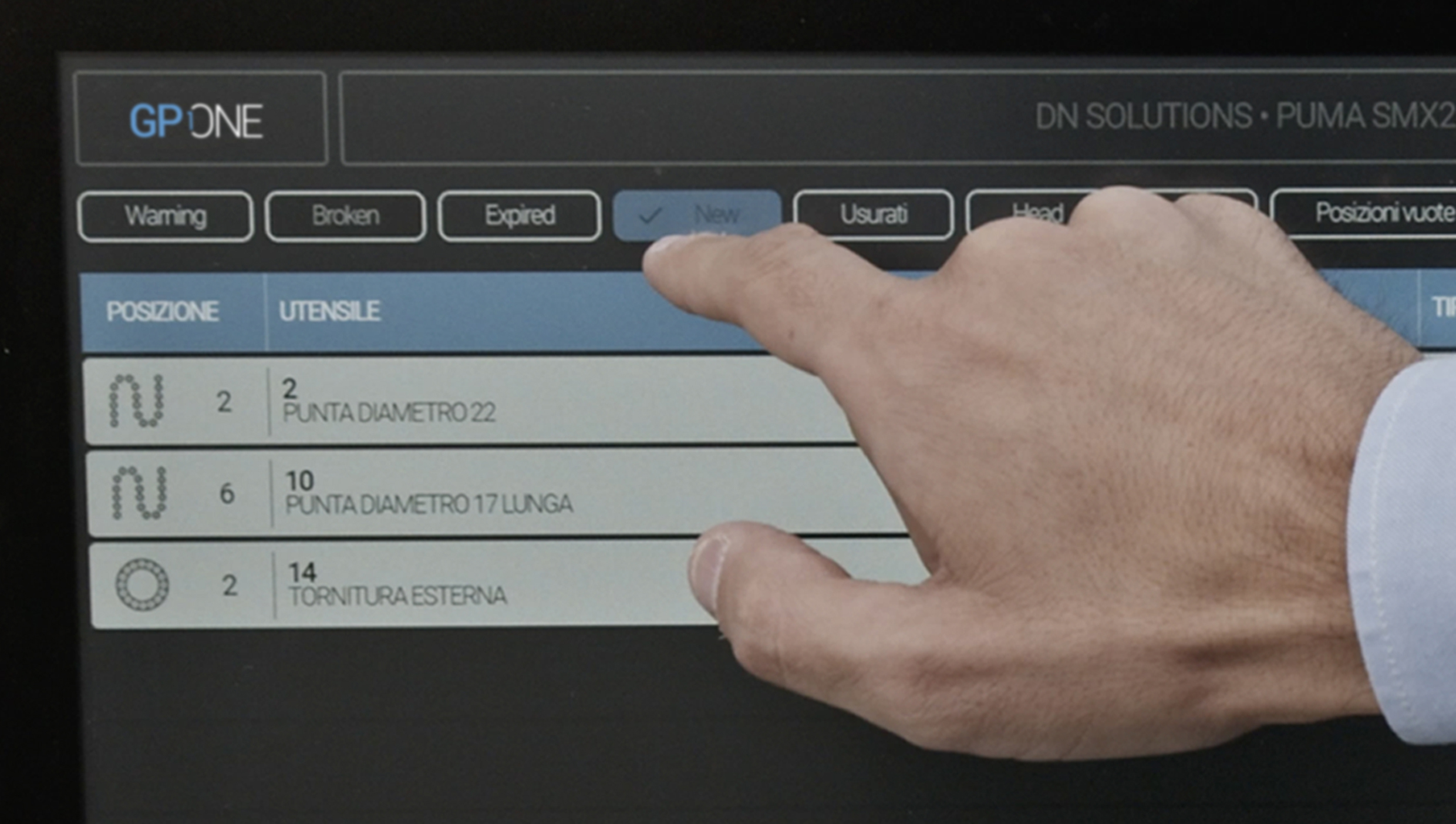

Trova quello che ti serve. Subito.

Grazie ai filtri avanzati, potrai decidere quali utensili visualizzare in base alle caratteristiche rilevanti e rendere la ricerca più veloce ed efficace.

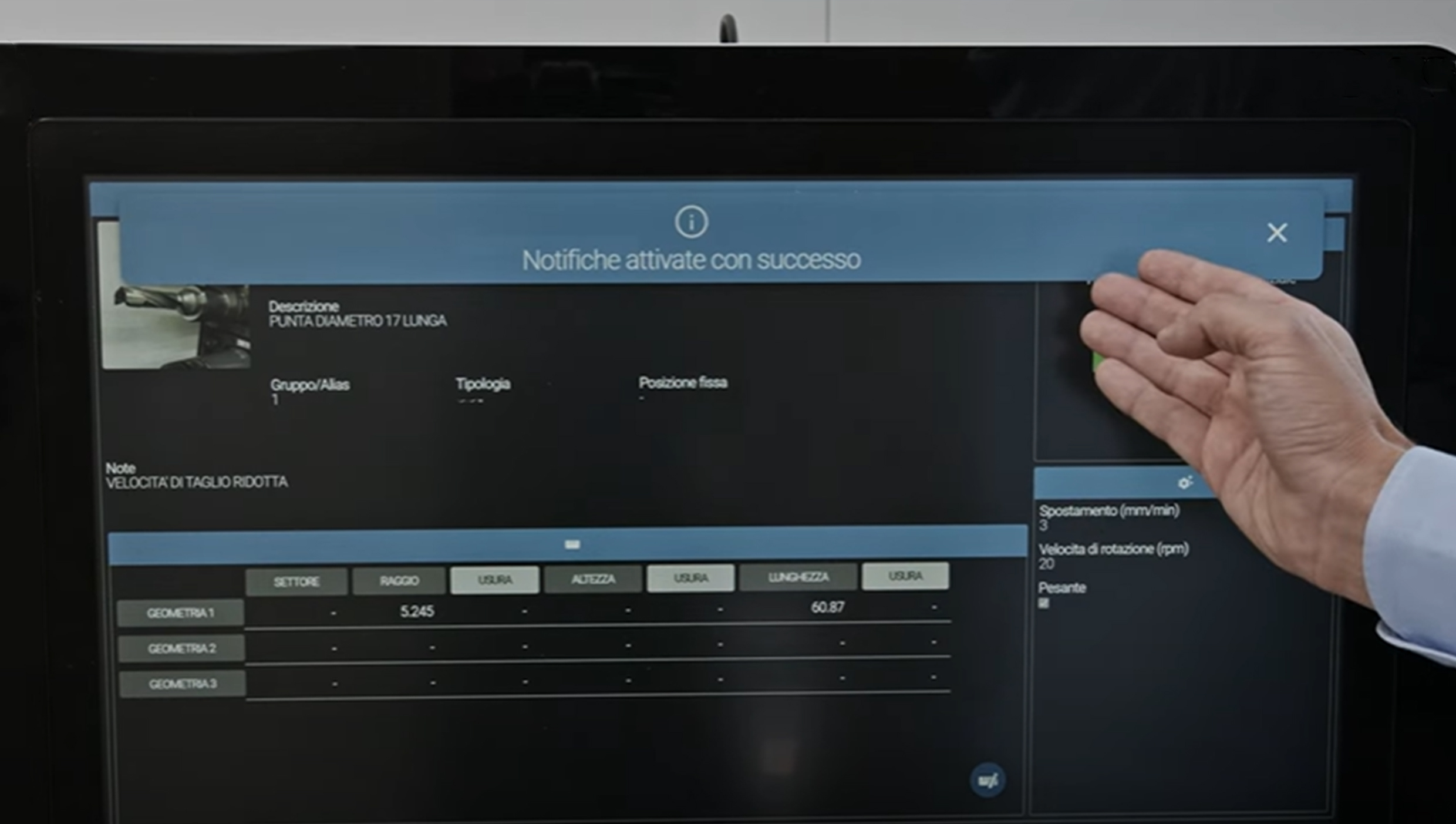

C’è un problema? GP ONE Tool ti avvisa.

Quando un utensile raggiunge lo stato di usura limite, il sistema rileva lo status in automatico ed invia una notifica al team leader evitando il fermo macchina.

Connetti le macchine della tua azienda.

Il software GP ONE Tool si interconnette con qualsiasi macchina CNC della tua azienda, con la possibilità di interconnettere più di una macchina alla volta.

Tanti vantaggi, un’unica soluzione.

Adottando GP ONE Tool per la tua azienda avrai un vantaggio economico rilevante: ottimizzi l’utilizzo degli utensili, velocizzi il caricamento a sistema, eviti l’errore umano da digitazione.

GP ONE Tool, inoltre, rientra nelle spese ammissibili del nuovo CREDITO DI IMPOSTA 2023, potendo così garantire l’accesso ad un aiuto fiscale del 20% sull’installazione. Grazie a questi elementi, è possibile rientrare nell’investimento in pochi mesi.

Inoltre, l’area GP ONE Tool può essere integrata con gli altri prodotti della suite GP ONE, come MES, Program e FMS, per offrire una soluzione completa e integrata per la gestione dell’azienda.