GP ONE MES

GP ONE MES is the software that allows monitoring the production, adapting to any type of machinery, whether it’s Industry 4.0 ready or traditional.

Thanks to advanced technology, the system offers effective signal management, ensuring high data stability and the ability to handle a large amount of information simultaneously.

GP ONE MES seamlessly integrates with the most common ERP systems. Moreover, the software allows for maximum freedom in creating indicators and KPIs, with the aim of monitoring company efficiency.

GP ONE MES enables tracking of production activities within a company, ensuring accurate recording and constant monitoring of work progress.

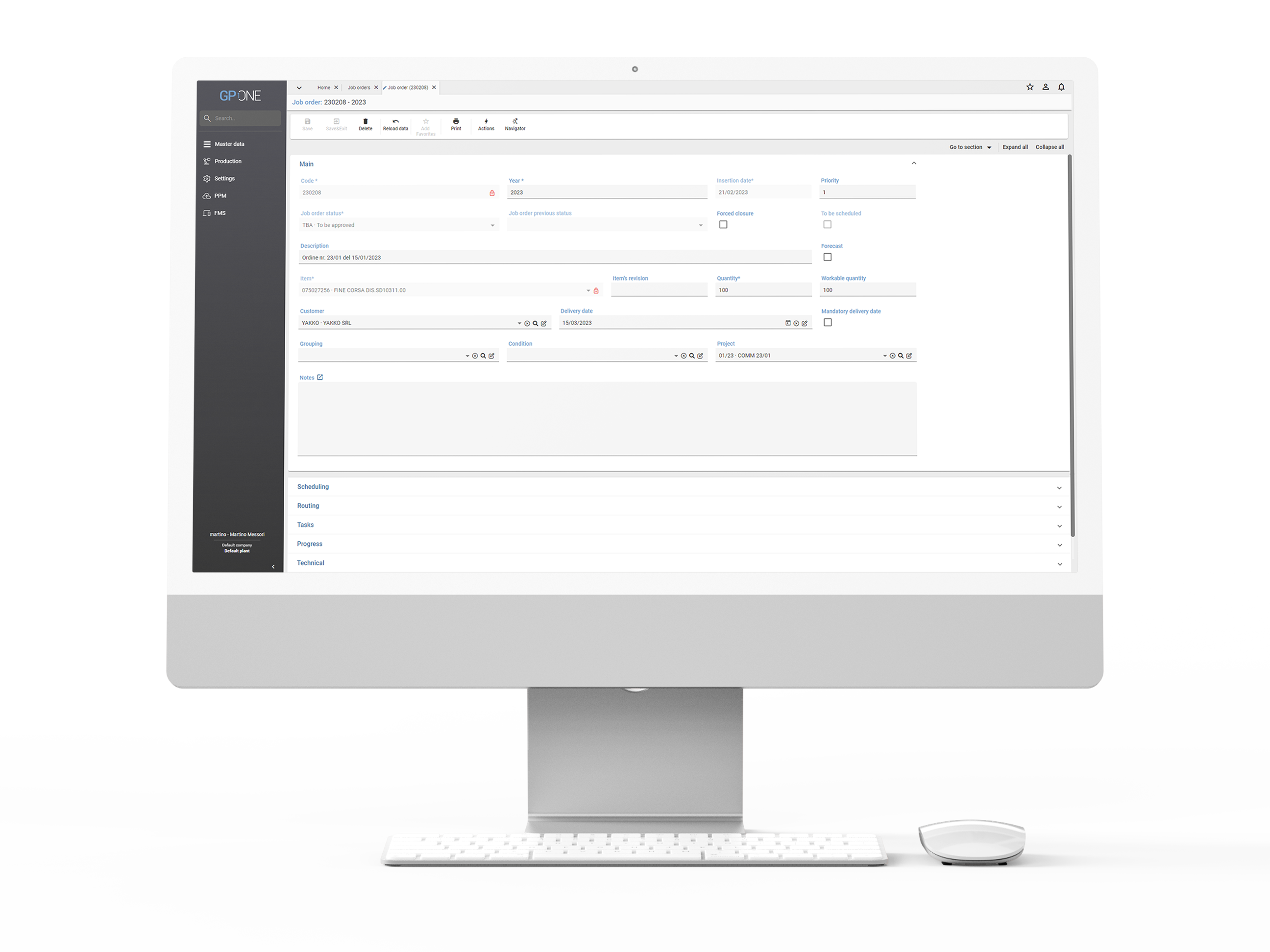

Among the main features, it is possible to include in the system the master data of articles with their respective processing cycles, company resources, and basic registry information.

You can create production orders or automatically import them from an external ERP system.

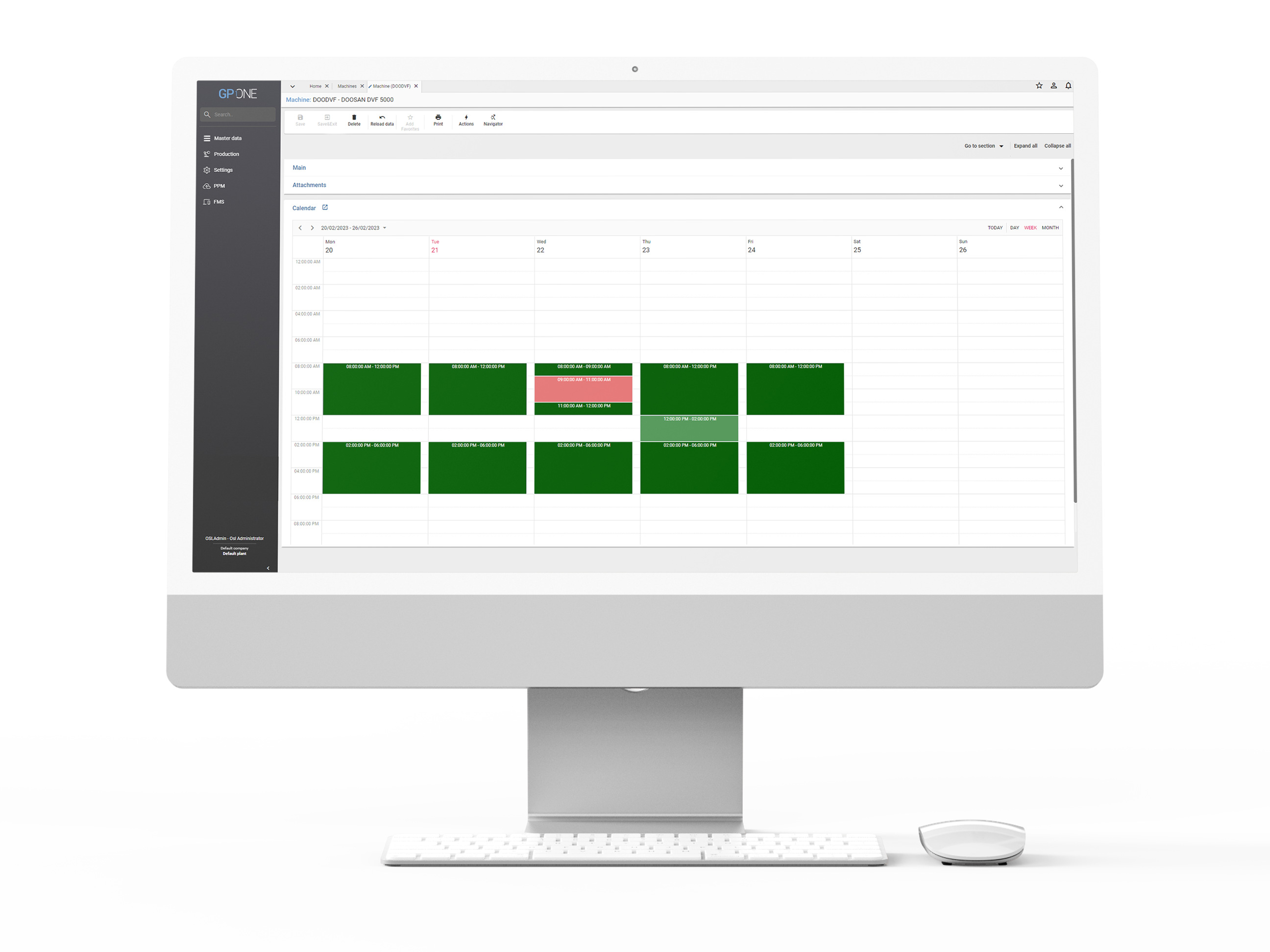

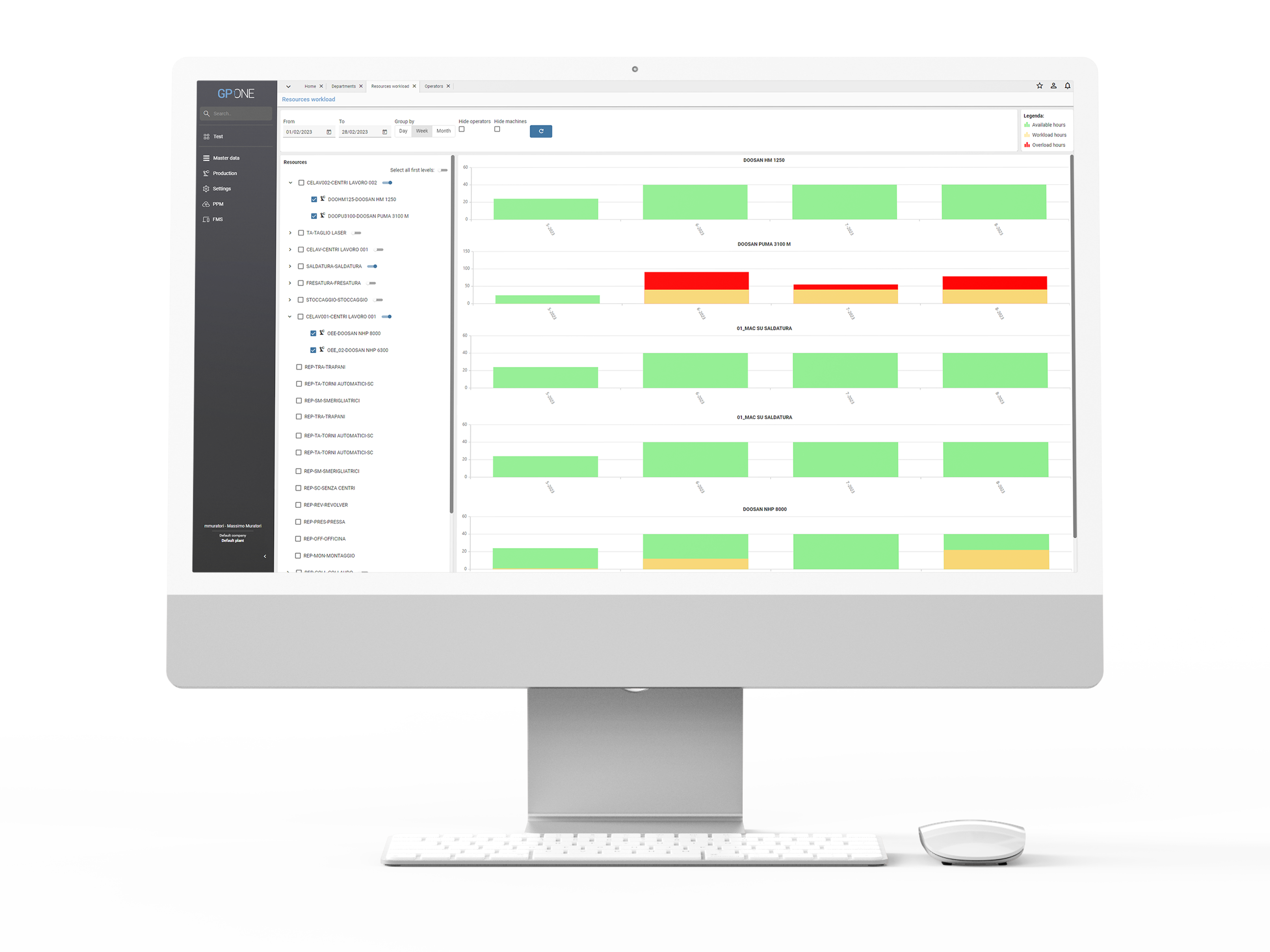

The system manages the production calendar of resources involved in the production cycle and is capable of infinite capacity planning for productions, estimating the workload of the resources.

Additionally, through dedicated workshop stations, operators can declare their activities, resulting in the recording of resources used, working times, and real-time progress of productions.

Work times and progress can be exported to an external ERP system, ensuring perfect integration between systems.

With this module, it’s possible to obtain a clear and complete view of the production activity, monitor times and resources used, and always have control over production progress.

Furthermore, GP ONE MES can be integrated with other products in the GP ONE suite, such as Program and Tool, to provide a comprehensive and integrated solution for company management.

Ask for a free consultation.

For more information on GP ONE and to be contacted by our experts for a free consultation, fill out the form below: